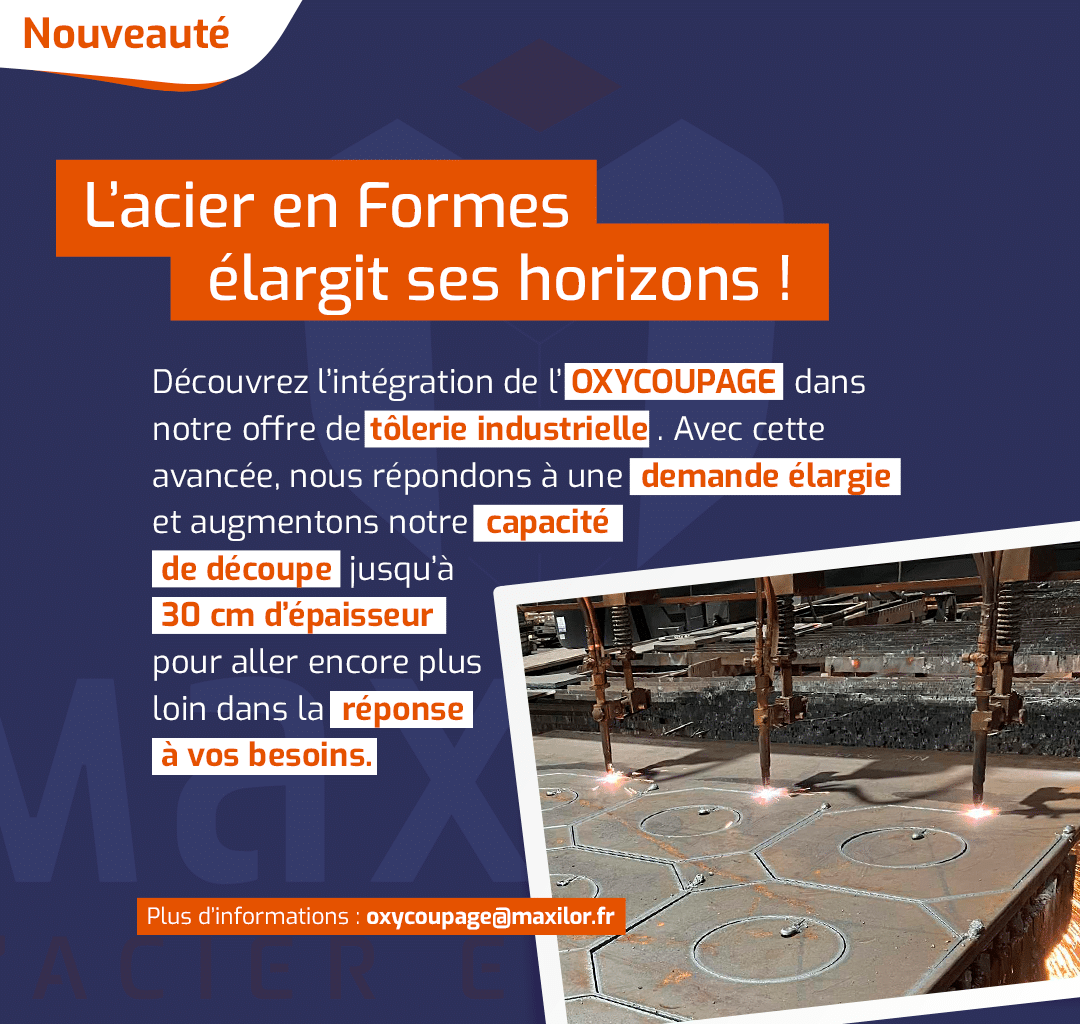

Maxilor

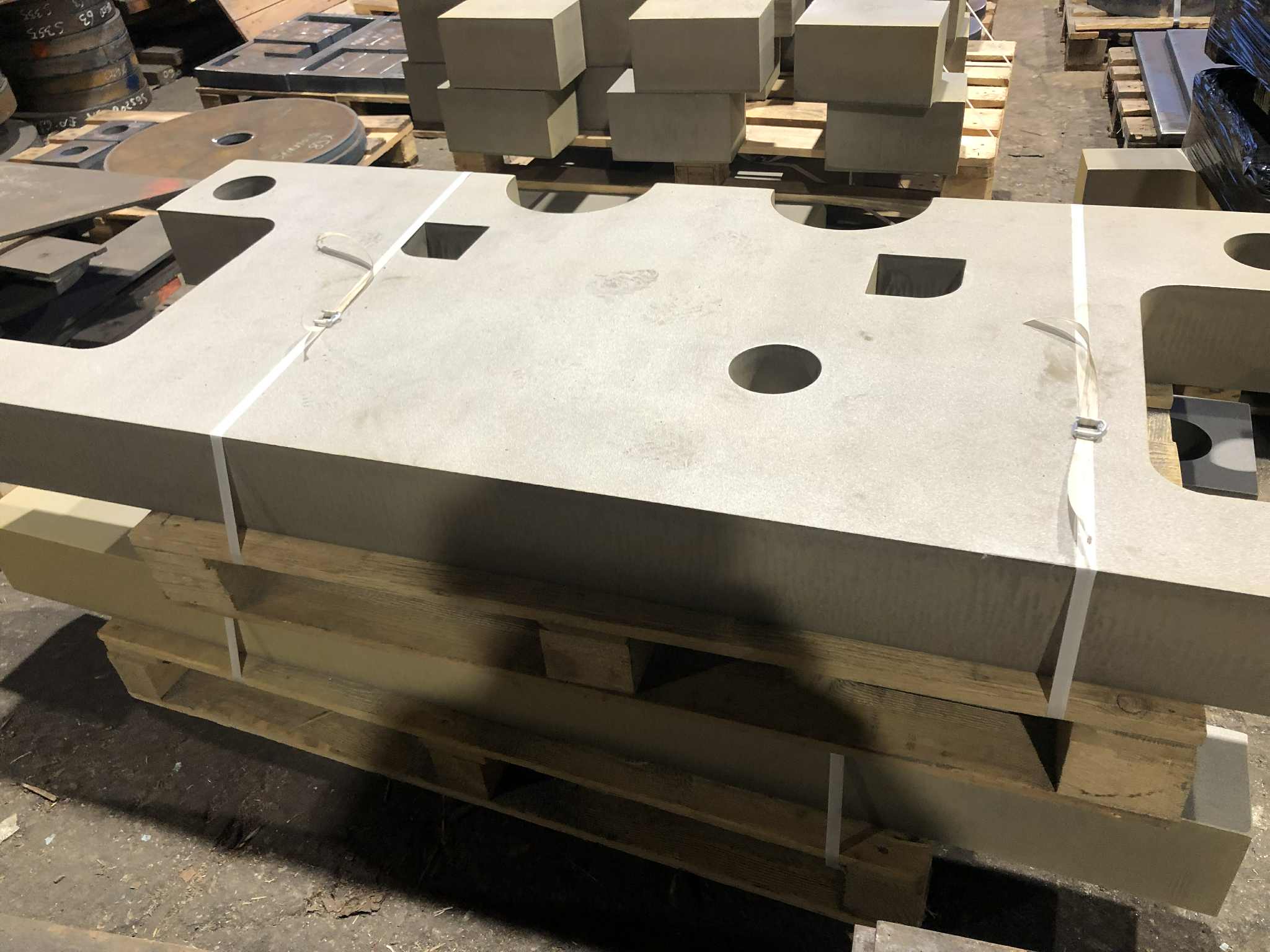

Oxycutting

Oxy-fuel cutting is a combustion-based cutting technique. A heating flame brings the steel piece to an ignition temperature of 1300°C. Then, a pressurized jet of oxygen from a torch is released and passes through the steel.